Valap brush

Valap is a soft wax used to seal around a coverslip when you put it on a slide, to keep it in place and prevent evaporation. It’s better than nail polish because it sets almost immediately and is non-toxic—so you can image live cells. It also stays relatively soft, so you can recover your sample if you need it back, or if you want to flow in a new solution you can easily break the seal, change the solution, and re-seal it in seconds.

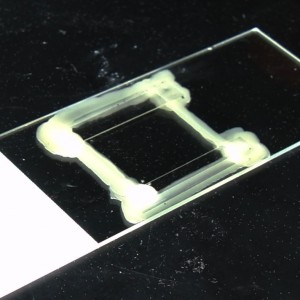

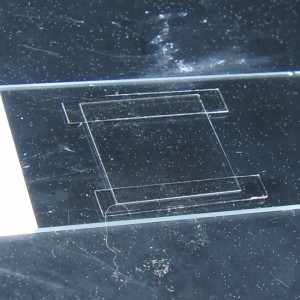

Figure 1: Two glass spacers (made from a cut-up coverslip) form a flow chamber by creating a gap between the coverslip and the slide

Valap is easy to make: just weigh out equal amounts of vasoline, lanolin and paraffin wax into a beaker, microwave until they melt, and stir well to mix.

The downside of valap is that it’s essentially wax—you have to melt it and paint it on. You can do this by putting a beaker of valap on a hotplate (or special wax warmer), but this takes some time to warm up and melt, and it is hard to paint on with a brush as it solidifies on the brush within a second or two.

To solve this, I made a valap brush—essentially a modified soldering iron, with a metal brush at the end. It heats up just enough to melt the valap—the solid valap melts as you touch the brush to it, then you paint the liquid valap on at leisure. :)

Figure 4: The end of the brush is made of two parts, a thick single-strand copper wire which coils around and supports a bunch of multistrand flexible wire that makes up the brush tip itself

To make one:

- Put a $10 lamp dimmer in the line (used to reduce the temperature of the iron to just enough to melt the valap)

- Coil some single-strand 16-gauge copper wire by wrapping it around something like a screwdriver, then bend the ends together and insert into the tip of the iron as shown (Figure 4). Tighten the screw to keep it in place—I had to put a couple more pieces of copper wire in there to pad out the gap and make a snug fit.

- Insert some flexible multistrand wire through the coil (I used some extra-flexible wire from Radio Shack and stripped off the insulation). Bend one end around to keep it in place and leave the other end sticking out to make the brush part of the tip.

- Plug in the iron, starting the dimmer switch all the way down, and gradually increase the dimmer until the iron tip is hot enough to melt the valap, but not so hot that it burns it. Once set to the right temperature, you might want to fix it in place.

I find that pouring the valap into a petri-dish (Figure 3) makes it easy to use with the iron. You should melt the valap with the copper part of the brush, which is quite rigid, then tip the brush to allow the liquid valap to flow onto the flexible brush tip for painting it onto the slide. Also, I put a piece of foil under the stand to catch drips (Figure 3; moved out the way to increase contrast in the photo.)